Discover Thermoelectric TEG Power

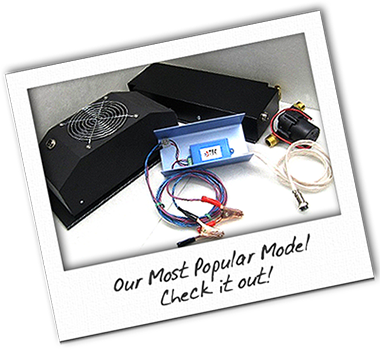

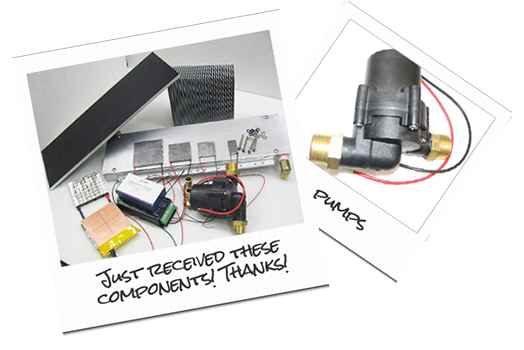

100 Watt Rabbit Ears wood stove Thermoelectric Generator

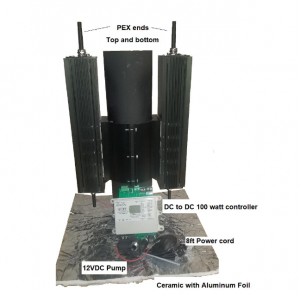

The system on right uses PEX machined tubes for easy plumbing and offers exceptional TEG design and versatility. The PLC can be optioned with Thermocouple hot side sensor for back feed control of pump. Example if stove temperature is below 100F the pump can be cycled on/off saving valuable power. The PLC also has a R-232 port for hooking up a computer for programming other functions. Future options include a automatic fire extinguisher which will discharge inert baking soda should a fire start in the top of your chimney. This feature will be a first of many features protecting you & your house against fires.

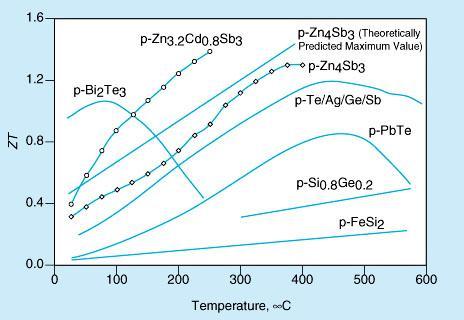

Bi2Te3 is the most efficient at room temperature. Material such as PbTe, work at 350 to 600° C (702-1112°F). Both Bi2Te3 and PbTe are mature material. Their characteristics and performance are well documented and have been used extensively in commercial application. PbTe however, is almost impossible to purchase commercially by itself in module form until now. Hybrid Thermoelectric module combining the best in class Bi2Te3 P-type with the best in Class PbTe N-Type material to form the first Hybrid TEG modules classed as a TEG1-PB series module. PbTe properties are better suited to temperatures above 300°C, so the combination works well in the 300°C to 360°C range. And now PbTe/TAGS up to 12% efficiency.

Other Green Technologies we offer

- “Hydrogen on Demand” using elemental materials to produce Hydrogen For heat and power from a fuel cell.

- Carbon DE-sublimation the most economic DE-Carbonizing technology commercially available today

- Industrial IoT sensors end to end solutions! Temperature, Vibration, humidity, Oil Contamination sensors!

The Four Classes Of Thermoelectric Generator Modules

- Bi2Te3(Bismuth Telluride) SERIES 1. Up To 320°C

- PbTe-BiTe (Lead Telluride/Bismuth Telluride) HYBRID SERIES 1 PB. Up to 360°C

- PbTe-TAGS ( Lead Tellurium/ Tellurium-Antimony-Germanium-Silver 12% efficiency up to 600C hot side)

- PbTe-PbTe ( Lead Tellurium /Lead Tellurium encapsulated up to 600C operating temperature.

- (Bismuth Telluride cold side) calcium Manganese Oxide hot side CMO CASCADE. Up to 800°C

- Calcium Manganese Oxide hot side CMO Up to 900°C