Tecteg Mfr. a division of TEC is currently developing a tubular or annular thermoelectric Seebeck device achieving an efficiency of approximately 6 to 7%. These annular or tubular power prototypes have been fabricated and are undergoing laboratory testing to determine their full specifications and performance curves under varying hot-side and cold-side thermal conditions.

A defining feature of these devices is that heat transfer occurs transversely to the direction of electrical current flow. This unique characteristic enhances power output performance and contributes to reduced overall system costs.

Thermal Electronics Corp. is anticipate the introduction of these devices into the Data Center Cooling Distribution Unit (CDU) market. Their deployment is expected to offer a significant efficiency advantage by enabling direct conversion of BTUs into electrical power (watts). This capability allows for effective scavenging of waste heat into usable energy in the form of watts (W), kilowatts (kW), and potentially even megawatts (MW).

By integrating this technology, data centers can greatly improve operational efficiency, reduce total electrical power consumption from the grid, and lower operational costs.

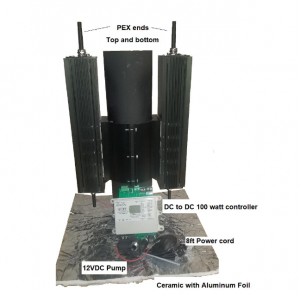

The First Truly Easy to Install 100W Thermoelectric Wood Stove Generator. That Actually Works!

Tecteg Mfr. manufactures cutting edge thermoelectric power generators. Over 30 years of design and manufacturing experience with a library of thermoelectric components that produce the best power output results bar none. Millions of dollars in R & D thermoelectric research and a no compromise product development approach offers cutting edge products second to none. The IPOWERTOWER Passive cooling 10 Watt thermoelectric Generator offer 10Watts of emergency power, Heat, hot water, with an output of 5V USB and 1.2V to 20V Auxiliary charging output. Nothing in the industry can compare. It’s patented design is second to no other thermoelectric product in it’s class. The Rabbit Ears 100W Thermoelectric Generator is another incredibly easy product to set-up on after market wood stoves. Again, well thought out design with a no compromise approach, in both performance and design. With decades of reliable power every time you run your wood stove, you’ll produce both power and hot water. Easily set-up for 12V or 24V continuous battery charging! And next year we will have a 200 Watt Thermoelectric Generator Rabbit Ears for 48V charging. All in the same dimensional size as the 100Watt TEG generator!!

Near Future

Tecteg Mfr. working with Jason Stewart “The Firemaster” and his clean burning wood stove adapter patented invention in New Zealand and with Derald Cook owner of intensofuergo in Chile who also is working with our group which developed a turn key clean burning wood stove adapter system to make older stoves not only more efficient but clean burning, the future design will option a thermoelectric power generator, with hot water and distributed heating and produce roughly 100 watts. CHP for short. The adapter will reduce will produce more heat from the same amount of wood.

Why Thermoelectric Power Generation?

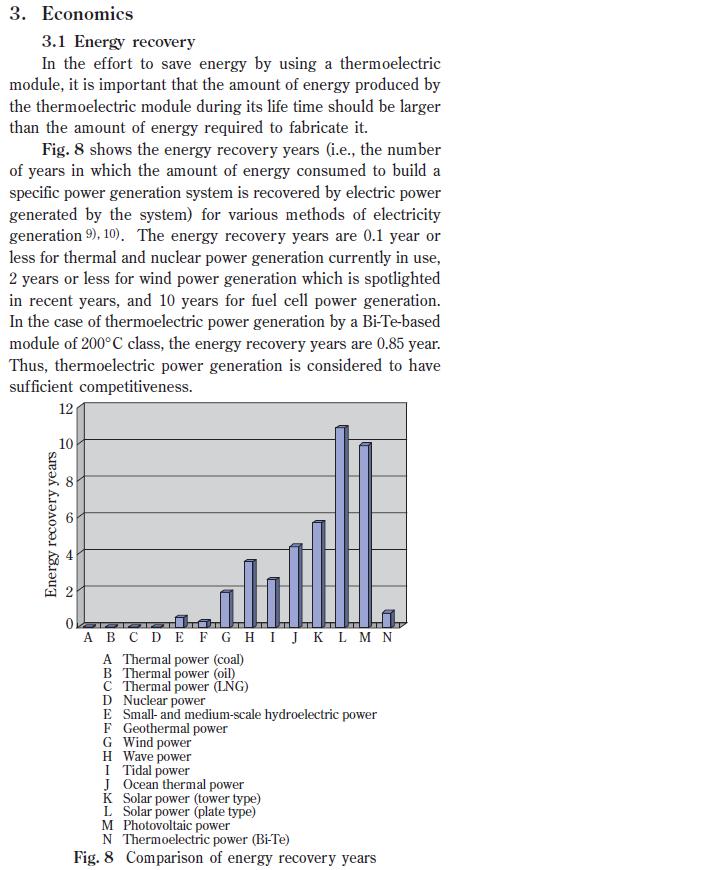

A big component of so called Carbon Reducing Technology is how quickly a technology will begin to produce a net power benefit. Basically, all green technologies either consume power or create a Carbon Footprint while being manufactured into a final product. The graph below shows several standard Green Technologies and the time it takes the power they produce to equal the power it took to manufacture them. If all Green Technologies were evaluated in this manner, Thermoelectric Generation would be the least carbon intensive of all green technologies.

It was obvious to us that Thermoelectric Power Generation (TEG) technology is by far the most competitive power neutral technology of all Green Technologies available. One might say that you need to burn fossil fuel to capture power and that adds to the ongoing power requirements?

The truth is that in 99% of the applications the fuel is already being consumed for other purposes. All we are doing is extending the life of that fuel and making the consumption more efficient! As in most cases the fuel is providing heat, or work. Each of these processes have waste heat as a by product. We are just consuming the heat before it is lost to the atmosphere. Presently we are working with McMaster University to validate our new technology. Once successful this technology could be widely implemented in everything from Furnaces, Cars, Trucks and Heavy Industry to name a few.