Thermal paste, thermal grease, heat sink compound, Graphite sheets– call it what you will, it’s really useful. How?

Though the surface of your newly purchased TEG seems smooth, it’s not. Same goes for that wood stove surface or housing that you’re attaching it to. Zoom in about 100X and the steel looks more like rock. In fact, looking at a microscopic cross-section without context one might think they’re looking at the Cliffs of Dover.

Air, of course, conducts heat; but very very poorly. Thermal paste or graphite sheets however, are formulated to fill in those air gaps. So by ‘filling in the cracks’ with thermal paste or Graphite you greatly increase the efficiency of heat transfer and along with it produce more power with your new TEG GENERATOR. But alas your work is not over. Take a look at the Thermal Transfer of some metals below! Silver, Aluminum and copper have superior heat transfer properties, but take a look at your stove. Carbon steel??? Iron??? Not great! These materials although great for building stoves don’t do much for transferring heat. They create limited heat transfer as per their Thermal Conductivity ratings below. Steel and iron limit TEG’s causing them to perform worse because the steel in stoves don’t allow heat to flow! Heat flow is CRITICAL FOR POWER GENERATION!

- 1 Btu/(hr oF ft2/ft) = 1 Btu/(hr oF ft) = 1.731 W/(m K) = 1.488 kcal/(h m oC)

| Metal | Temperature – t – (oF) |

Thermal Conductivity – k – (Btu/(hr oF ft)) |

|---|---|---|

| Aluminum, pure | 200 | 124 |

| 400 | 144 increase with higher temperature superior performance | |

| Carbon Steel, max 0.5% C | 68 | 31 low conductivity POOR |

| Copper | 572 | 32 decreases with higher temperature |

| 1832 | 20 POOR (MUCH LOWER CONDUCTIVE PROPERTIES) |

|

| Iron, wrought | 68 | 32 |

| Silver, pure | 68 | 235 |

| Stainless Steel | 68 | 7-26 |

| Wrought Carbon Steel | 32 | 34 |

- T(oC) = 5/9[T(oF) – 32]

- 1 Btu/(hr oF ft2/ft) = 1 Btu/(hr oF ft) = 1.731 W/(m K) = 1.488 kcal/(h m oC)

SO what to do about the POOR THERMAL TRANSFER

Vola!

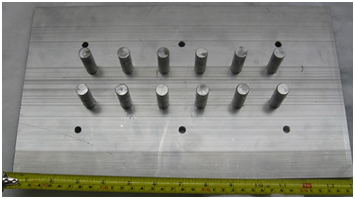

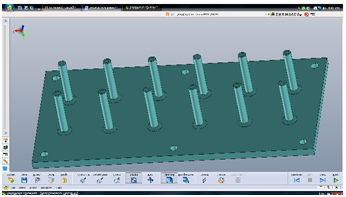

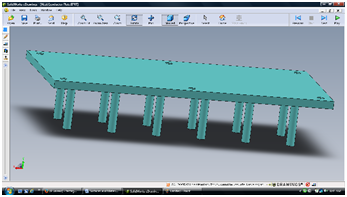

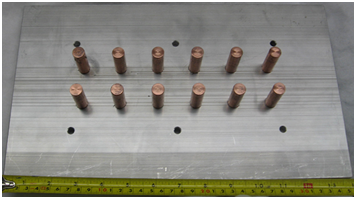

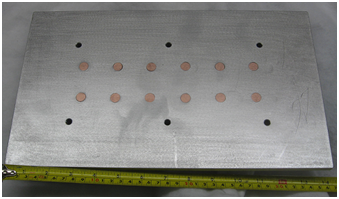

Each rod below is made of Copper or Aluminum. A total of 12 rods each centered to the TEG array of 12 modules which, is found on our TEG12VDC-24LIQUID thermoelectric generator system. We will be testing this new TEG Heat Transfer Plates at the College of Caledonia to provide real data on performance and power output using a typical wood stove. We are testing both material because some published literature suggest that as temperature rise copper starts to lose its thermal conductive properties, so we will test both aluminum and copper rod to determine if this is indeed correct. Surprisingly, there is little or no data pertaining to the Thermal Conductivity of Copper at elevated temperatures. We also want to determine and prove that if we use this material that they move enough heat so well that they never reach melting points of the Aluminum. Our past tests have confirmed this but with a flat plate. This is the first design that has pin fins extracting heat from the fire.

Copper Pin fins

Aluminum pin fins